Spec springs, often overlooked but critical components in various industries, play a pivotal role in ensuring machinery and systems operate seamlessly. These specialized springs are engineered to meet industry-specific requirements, providing precise levels of force and resilience. In this blog post, we will dive deep into the intricate process of customizing spec springs for diverse industrial applications, highlighting the importance of precision engineering and collaboration with experts like Marathon Sales.

The Significance of Spec Springs

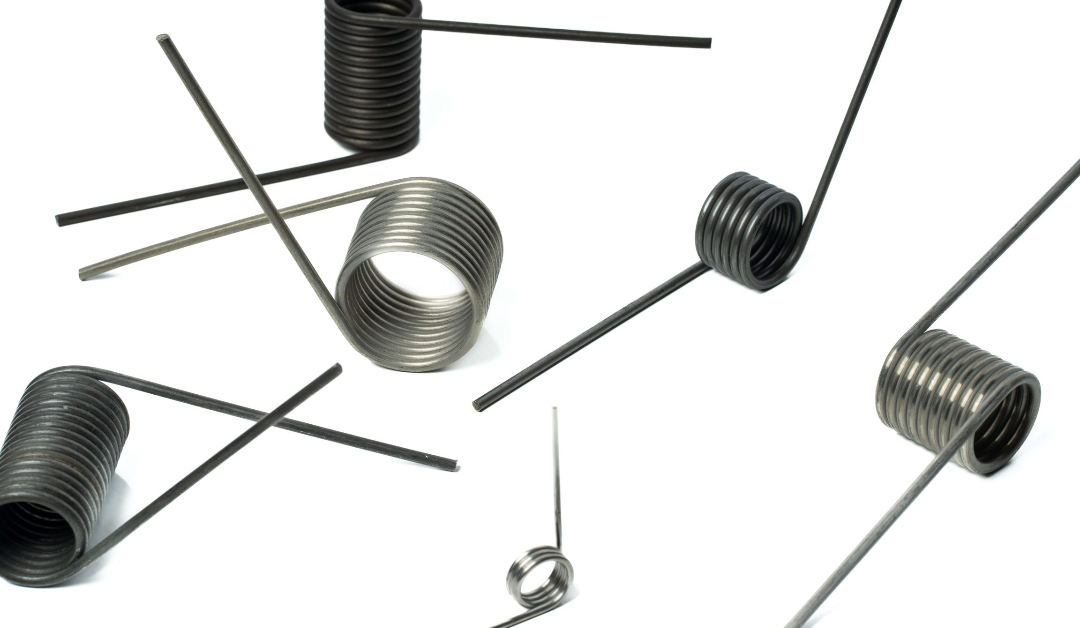

Spec springs are vital in various industries due to their capacity for precise customization and robust performance. In the automotive sector, they enhance vehicle stability and comfort by absorbing shocks and vibrations. Aerospace applications rely on spec springs for critical functions like landing gear operation and control surface movement, emphasizing safety and reliability. In industrial machinery, they provide essential torque and rotational force for heavy-duty processes. These springs’ versatility, capable of handling heavy loads and resisting fatigue, makes them indispensable across sectors.

Challenges in Customization

Customizing spec springs presents several challenges that need to be meticulously managed to ensure these components meet the diverse and stringent requirements of various industries.

Material Selection: The choice of material is crucial in spring design. Different materials like carbon steel, stainless steel, nickel alloys, titanium, and composites each have unique properties, making them suitable for specific applications. Factors such as tensile strength, corrosion resistance, and temperature tolerance are critical considerations. For example, carbon steel is often used for high-load applications due to its strength and durability, while stainless steel is preferred in corrosive environments. The chosen material needs to balance cost-effectiveness with performance requirements.

Precision Engineering: Designing springs to meet precise specifications requires an in-depth understanding of mechanical engineering principles. Minor deviations in design can lead to significant operational issues. For high-precision technical springs, the challenge is to balance precision with maintaining strength and durability. Techniques like computer simulations and prototyping are employed to optimize design parameters and validate the designs before production. This approach minimizes the risk of errors and ensures the spring meets the specific requirements of the application.

Performance Enhancement: Customization goes beyond meeting basic standards; it aims to enhance the performance of the systems in which the springs are integrated. This involves not only achieving the required load-bearing capacity and durability but also ensuring that the spring’s performance aligns with the overall system’s efficiency and effectiveness.

Specific Challenges in Compression Spring Design: Specific to compression springs, designers face challenges like selecting the appropriate slenderness ratio and spring index, which impact the spring’s stability and manufacturability. The slenderness ratio, which is the ratio between the spring’s coil diameter and free length, needs to be managed to avoid issues like buckling and deflection. The spring index, the ratio of the mean diameter to the wire diameter, influences how tightly wound the coils are and affects the spring’s manufacturability and functionality. Moreover, loading capacity is a critical factor; the spring must be able to support its maximum safe load without risking catastrophic failure. This involves careful consideration of the spring’s dimensions and material properties.

Overall, designing and customizing spec springs is a complex process that requires a harmonious blend of material science, precision engineering, and performance optimization. Working with experienced manufacturers and utilizing advanced design and testing techniques is essential to overcoming these challenges and ensuring the development of springs that meet the specific needs of various industrial applications.

Case Studies: Real-World Solutions

Let’s take a closer look at how customized spec springs have provided real-world solutions in various industries:

Automotive Excellence

In the automotive industry, where precision is paramount, customized spec springs are used to achieve optimal vehicle suspension. These springs are designed to absorb shocks, provide stability, and ensure a comfortable ride. By tailoring the springs to meet specific vehicle requirements, manufacturers can enhance both safety and performance.

Aerospace Advancements

Aerospace applications demand the utmost precision and reliability. Spec springs are employed in aircraft landing gear systems, where they must withstand immense loads and ensure smooth landings. Customization allows engineers to design springs that excel under extreme conditions, contributing to the safety and success of aerospace missions.

Manufacturing Mastery

In manufacturing, where efficiency is key, customized spec springs play a crucial role in machinery and equipment. These springs are designed to provide consistent force, reducing downtime and optimizing production processes. As a result, manufacturers can achieve higher output and maintain a competitive edge.

Collaboration with Marathon Sales

The journey of customizing spec springs involves close collaboration between engineers and clients. One notable partner in this field is Marathon Sales, known for its expertise in engineering precision solutions for diverse industrial applications.

Marathon Sales understands the unique challenges faced by industries and works closely with clients to develop tailored spec spring solutions. With a commitment to excellence and a deep understanding of materials and engineering, Marathon Sales ensures that spec springs not only meet but exceed expectations.

Concluding Thoughts

The customization of spec springs is a nuanced and technical process essential for meeting the specific demands of various industrial applications. The success of these springs in enhancing system performance lies in expertly navigating challenges in material selection, engineering precision, and performance enhancement.

For those in industries requiring specialized spring solutions, Marathon Sales offers the expertise and experience needed to deliver customized, high-performance spec springs. Contact Marathon Sales for expert guidance and high-quality custom springs. Enhance your project’s performance today!